1853

BRIGHTON 17th MARCH 1853

INVOLVING BRIGHTON ENGINEMEN DRIVER JOHN YOUNG, FIREMAN JOHN ELLIOT, AND LOCOMOTIVE FITTER RICHARD BAKERDUE TO THE EXPLOSION OF LOCOMOTIVE No. 10 ‘MARS'

PHOTOGRAPHER UNKNOWN

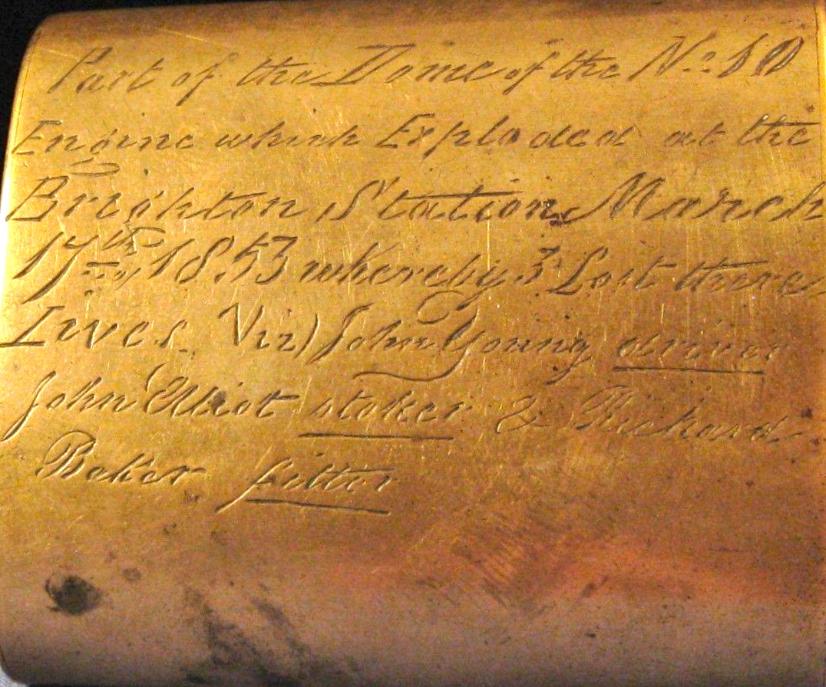

Engraving on a commemorative snuff box,

made from the brass dome of locomotive No. 10 'Mars'

Brighton residents were dramatically reminded of the railway industry in their midst on 17th March 1853 when 'a loud report resembling the explosion of a large cannon' startled Mr. Craven (Locomotive Superintendent for the L.B.S.C.R.) as he was about to begin shaving. It came from the station, and witnesses reported that a mass of smoke and vapour enveloped everything, but as it cleared off it was seen that a large portion of the western most shed was blown off, and upon the remaining portions were fragments of an engine.' These were the remains of a a 'Rennie Single' tank engine No. 10 'MARS’, whose boiler had blown up shortly before it was due to depart with an early morning train for Littlehampton. No. 10, said to have been cut down from a larger engine, had recently been through the works, and with the driver and fireman on this occasion was a fitter who was to watch its performance. All three were killed. an official statement quickly issued by the L.B.S.C.R. said that the Directors "had too much cause to believe that the accident arose from the driver having screwed down the safety valves shortly before the accident took place."An inquested was held, and Craven was closely questioned by the jury over supervision in his works. No connection could be established between the work which had just been carried out on No.10 and the cause of the explosion but the jury was clearly uneasy about the number of changes that had been made since the engine was new in 1840. In a phrase giving a glimpse of methods, Craven explained that 'engines are like an Irishman's coat; they are patched and patched till they are nearly re-built.’

Evidently the safety valves had been in order to start with. The assistant stationmaster had 'observed that driver John Young was standing up on the hand railing by the side of the boiler warming his coffee at the top of the safety valve, the steam from which was blowing off.' Craven was further questioned about his encouragement to enginemen to save steam, which might have led them to tamper with the valve settings, but the line of inquiry proved inconclusive. On the other hand evidence from other railwaymen did show that driver John Young on that day had made adjustments. The inquest was adjourned after 6 1/2 hours. When it was resumed the next day the jury's verdict was 'that the death of the driver, John Young, was caused by his own reckless conduct in placing a higher pressure on the engine than it was fitted to bear.' Driver John Young was found guilty of manslaughter in causing the deaths of two colleagues on the footplate. All members of the jury concurred in and recommendation that 'in future a more frequent and rigid examination be made of the locomotive engines.'

BRIGHTON

17th March 1853

INVOLVING BRIGHTON ENGINEMEN

DRIVER JOHN YOUNG, FIREMAN JOHN ELLIOT,

AND LOCOMOTIVE FITTER RICHARD BAKER

extracted and adapted from the report by

Douglas Galton

Captain Royal Engineers

On the 17th March 1853 an accident occurred at Brighton from the explosion of the boiler of an engine belonging to the London, Brighton, and South Coast Railway Company.

It appears that the engine in question, No.10, had been sent on the 4th of March into the workshops in consequence of the breakage of a cylinder cover and I was informed that the fire box casing was stripped off and the top of the fire box examined; that the inside of the fire box was also examined and the stays sounded, and that everything appeared to be right. The engine was ready to go out on the 15th March; on the 16th it was moved out of the workshops, and on the morning of the 17th the fire was lighted at about half past four a.m. It was moved with steam to the coke sheds at six a.m., and the driver took charge at a quarter to seven a.m., and moved it from the coke sheds to the Portsmouth passenger platform, accompanied by the night locomotive foreman. This man states, that he left the engine at four or five minutes after seven, and the water was then within an inch of the top of the glass water gauge, which would be more than seven inches above the top of the fire box, and the valves were set at under eighty pounds pressure, and that the steam was blowing off strong at the safety valves. There were two valves; one on the firebox and the other on the dome. An engine driver who had previously driven this same engine on the Eastbourne Branch, happened to be with a goods engine forty or fifty yards off, and he states that he observed the driver of engine No. 10. screw down the dome safety valve, and that no steam was blowing off from the other valve at that time, and that when the driver had screwed it down to over 100 pounds, he went to him and told him that eighty pounds was plenty for the engine and was the pressure at which it had been worked; he says the driver did not answer, but moved the engine back to the train. This man says, that the driver continued to screw down the valve till the steam ceased blowing off, but that half a minute before the explosion it commenced to blow off tremendously.

The engine was a tank engine at the time of the explosion. It is stated to have had 12 inch cylinders, and the length of stroke to have been eighteen inches. The driving wheels were 5 feet 6 inches diameter, and the leading and trailing wheels 3 feet 6 inches; the diameter of the boiler was 3 feet 4 inches, the length 8 feet. The tubes were 2 inches internal diameter and 101 in number; the fire box surface was about 44 square feet; the tube surface about 450 square feet, and the area of grate 10.75 feet. There were two safety valves of 2-.1, inches diameter each, fitted with Salter's balance, which I was informed could be screwed down to 130 pounds pressure, but I have not seen them amongst the fragments.

The engine was delivered by Messrs. Rennie to the company in October 1840, and is stated to have been used for ballasting till the opening of the line in 1841, but of the miles run by it during that period no record has been kept.

Its original cost was 17401. In the summer of 1844 it was transferred from the Brighton Company to the Joint locomotive committee of the Dover, it had new tubes in August 1844. In August 1845 it was transferred back again from the locomotive locomotive committee to the Brighton Company, and it is then shown to have run 11,636 miles under the Brighton company and 11,308 miles under the locomotive committee, making 22,944 miles in all. From the 31st March 1847, it ran 15,340 miles, and then was sent to Messrs. Collier, Chrisite and Adams for a new firebox. It began to run again on the 28th of January,1848, and ran till the summer of 1849, a distance of 82,891miles, when it was altered into a tank engine, from which time up to the 4th March, 1853, it ran 62,173 miles, with occasional repairs, thus making a total distance of 129,273 miles, exclusive of the miles run in ballasting before the line was opened.

I found the thickness of the plates of the boiler to be generally full five- sixteenths, but in some parts along the line of the fracture it was only a quarter of an inch. The boiler was made of tour plates carried length ways along the boiler, as shown in the sketch. This is a much weaker form of boiler than when the plates are bent round; the rivetting was single rivetting; the upper firebox, although bent, was not torn, and the stays appeared good; there was a lead plug in the top of the fire box. The boiler had been thoroughly examined six months before the accident, in the usual manner, by sounding and drilling boles in parts.

To account for this explosion, it has been stated that the driver screwed down the safety valves so far as to prevent them from acting, and that consequently a very high pressure was generated on the boiler.

The evidence is contradictory upon the point as to whether the boiler was blowing off the steam up to the time of the explosion or not. There appears, however, to be no doubt that the safety valves were screwed down considerably beyond the 80-1b. pressure, and if these valves did not fit well, (and it does not appear that they were examined the last time that the engine was in the shop) there might have been a partial escape of steam. Now there is no apparent flaw in the boiler which would prima facie account for its bursting at a low pressure, and according to Fairbairn's experiments, and making a deduction for any difference of strength on account of the single rivetting, its bursting pressure should have been above 350-lbs. per square inch, if sound.

This pressure could only have been attained by the valves being screwed down so tightly as to prevent any escape of steam, or if not screwed down, by their not having been of sufficient size to carry off the steam as fast as it was generated.

If the valves were screwed down, they could only have been in that position at most for ten minutes, according to the statement of the locomotive foreman, who was on the engine ten minutes before the explosion. In order to test the time which is required for the pressure of steam to rise in a boiler when the valves are screwed down, an experiment was tried with the sister engine to the one which exploded. It was found, that with a good fire, steam was got up to 30lbs. pressure in one hour and fifteen minutes; it required nine minutes to mist from 30 lbs. to 60 lbs., three minutes from 60 lbs. to 70lbs., and the same time from 70 lbs. to 80

lbs. The quantity of heat which is required to raise the pressure of steam is very much less per pound at high temperatures than at low ones, and hence with a similar fire the time required would also be much less. But even upon this assumption, the pressure, could not, I imagine, have risen in the ten minutes to above 170 lbs., or 200 lbs. pressure per square inch,which was still much under what the boiler should have borne if sound.

As there was some doubt from the evidence, as to whether the valves had not allowed the escape of steam up to the time of the explosion, in which case the pressure must have risen in the boiler in spite of this escape—I have endeavoured to ascertain the size of aperture which would allow of the escape of steam at different pressures. Mr. Daniel Gooch, the locomotive superintendent of the Great Western Railway, kindly undertook to make an experiment upon this subject, of which the following are the mean results.

The experiments were made with a boiler having a fire box surface of 162 square feet, and a tube surface of 1727 square feet, total 1919 square feet heating surface—and a grate area of 25.47 square feet. The pressures were shown by a Bourdon's pressure gauge.

With a pressure of 100-lbs. per square inch of steam, the area of the orifice required to keep the steam at that pressure was 0.65 inches

Ditto 80-lbs = 0.75 inches

Ditto 60-lbs = 1.06 inches

Ditto 40-lbs = 1.6 inches

Ditto 20-lbs = 3 this last was not satisfactorily ascertained as the water was getting low.

It will be observed that the area diminishes as the pressure increases.

I have assumed a formula from these results in which the grate area and heating surface in the fire box is included, omitting the tube area because the safety valves are for the purpose of providing for the safety of the engine when not working, and during that time the tube surface is comparatively inactive.

Supposing that for the escape of steam the valve is lifted one-sixteenth ofan inch, and that d = diameter of aperture of valve in inches.

S = heating surface of firebox. in feet

G = area of grate. in feet

P = pressure of steam per square inch in lbs.

d = S

P.G. 0196.

From this formula it would appear that one valve 2.6 inches in diameter lifted one-sixteenth of an inch would have sufficed to carry off all the steam that could he generated by the engine No. 10, at 80-lbs. pressure, and the higher the pressure rose, the less would be the size of the aperture required for carrying off the steam; consequently, as the engine had two safety valves of 2.5 inches each in diameter, if the steam was blowing off at all, a considerable check would have been afforded to the rise of pressure—and this tends to confirm what I have stated above, viz., that I conceive the boiler exploded at a pressure below what it should have borne if sound.

Again it is well known that there are causes of deterioration constantly going on in boilers. A chemical action is always at work to a certain extent in boilers which acts upon the surface of the iron, which it gradually removes, and so lessens the thickness of the plates ; this action is dependent to some extent on the quality of the water employed. It is also probable that a galvanic action is induced in parts, particularly adjacent to the firebox, where two metals, copper and iron, are in close proximity. A third action, which appears to be constantly at work, is a mechanical action, in consequence of an alteration in the shape of the boiler, resulting from the temperature and pressure of the steam.The continued action of a slight bending backwards and forwards of the plates at the same place, and the pressure with which the water is forced against this injured part may account for many of the appearances which are presented by deteriorated plates of boilers, such as long seams, &c.

Now I have obtained the following facts relative to the engine No. 10, from the original builders Messrs. Rennie. According to the record of the engine in their books the thickness of the plates of the cylindrical part of the boiler was when new three-eighths, and the plates on the outside case of the fire box were seven-sixteenths, the thickness of the plates I found to be after the explosion generally five-sixteenths full, but in parts of the cylindrical portion of the boiler four-sixteenths. Upon the subject of the safety valves the following is recorded viz. : " Limit of pressure of the safety valve not under control of engineer 601bs. The other valve under the control of the engineer 501bs. working pressure."It would therefore appear from this information, that whilst the thickness of the plates in the boiler of the engine had diminished by wear, as much as one third, in some places the pressure at which the engine was worked was increased by as much as one-third over the original pressure, and that the safety valves were altered so as to place both valves under the control of the driver, by which means the pressure of 80 1bs. might easily be exceeded. Now the effect of an increased strain with a diminished power of resistance would very much increase a mechanical action of the nature above described, caused by a continued alteration of shape from the variation of pressure.

It is stated that the boiler was thoroughly examined six months before the accident, but the only time when the interior of a boiler is thoroughly examined is when a new firebox and new tubes are being put in. At other times it is examined as was the boiler in question, by being sounded all over with a hammer; and if the sound at any places indicates that the plates are thinner than at other places, holes are bored into the plates to ascertain their actual thickness. This method of scrutiny does not however always detect those seams which are sometimes found to occur in boilers, and deterioration might have taken place in the boiler in question without being discovered by the examination it underwent. A water pressure is sometimes applied to boilers to test them; but this does not fulfil all the conditions of the pressure by steam, as the expansion of the metal by heat is omitted, and there is always danger of injuring the rivets by straining them too much above what they are intended to bear permanently.

Perhaps the best test would be a steam pressure up to a point somewhat above that at which engine is intended to be worked to permanently ; a careful register being mark at the same time of any alteration of shape which the boiler undergoes.

Under the above circumstances it appears to me that it was incurring a very great risk, to allow an old engine with a form of boiler weaker than that now in use and constructed for a working pressure of from 501bs. to 601bs., to he worked to 80 lbs., and that this risk was much increased by placing both valves under the control of the driver, without even ordinary precautions having been taken top revent him from being able to screw them down, probably to such a point as to prevent any escape of steam whatever, and at the same time giving the driver a premium to work with as high a pressure of steam as possible. The

Brighton Company have been in the habit of giving a half-yearly premium to those of their drivers who worked with the smallest amount of coke per mile. Now since the amount of heat which is required to raise steam a pound in pressure is very much less at high pressures than at low pressures, and that the higher the pressure the more expansively can steam be worked; this premium on a saving of coke is a premium on working with a high pressure.

If a railway company considers it desirable to give a premium of this descripiton (the expediency of which I do not here discuss), it is their duty to determine the limit of the pressure at which the engines may be safely worked, and they are bound to adopt all the precautions in their power to prevent these pressures from being exceeded, by placing one valve out of the control of the driver, and so arranging the other valve that it should not be able to be screwed down sufficiently to prevent any escape of steam. If efficient arrangements upon these points were introduced, and if it was made the duty of the locomotive foremen at the several stations to examine the valves of every engine whenever it came in or went out, I am of opinion that any undue tampering with the valves on the part of the engine drivers would be prevented.

The engine was delivered by Messrs. Rennie to the company in October 1840, and is stated to have been used for ballasting till the opening of the line in 1841, but of the miles run by it during that period no record has been kept.

To account for this explosion, it has been stated that the driver screwed down the safety valves so far as to prevent them from acting, and that consequently a very high pressure was generated on the boiler.

lbs. The quantity of heat which is required to raise the pressure of steam is very much less per pound at high temperatures than at low ones, and hence with a similar fire the time required would also be much less. But even upon this assumption, the pressure, could not, I imagine, have risen in the ten minutes to above 170 lbs., or 200 lbs. pressure per square inch,which was still much under what the boiler should have borne if sound.

Ditto 80-lbs = 0.75 inches

Ditto 60-lbs = 1.06 inches

Ditto 40-lbs = 1.6 inches

Ditto 20-lbs = 3 this last was not satisfactorily ascertained as the water was getting low.

It will be observed that the area diminishes as the pressure increases.

I have assumed a formula from these results in which the grate area and heating surface in the fire box is included, omitting the tube area because the safety valves are for the purpose of providing for the safety of the engine when not working, and during that time the tube surface is comparatively inactive.

S = heating surface of firebox. in feet

G = area of grate. in feet

P = pressure of steam per square inch in lbs.

d = S

P.G. 0196.

From this formula it would appear that one valve 2.6 inches in diameter lifted one-sixteenth of an inch would have sufficed to carry off all the steam that could he generated by the engine No. 10, at 80-lbs. pressure, and the higher the pressure rose, the less would be the size of the aperture required for carrying off the steam; consequently, as the engine had two safety valves of 2.5 inches each in diameter, if the steam was blowing off at all, a considerable check would have been afforded to the rise of pressure—and this tends to confirm what I have stated above, viz., that I conceive the boiler exploded at a pressure below what it should have borne if sound.

Brighton Company have been in the habit of giving a half-yearly premium to those of their drivers who worked with the smallest amount of coke per mile. Now since the amount of heat which is required to raise steam a pound in pressure is very much less at high pressures than at low pressures, and that the higher the pressure the more expansively can steam be worked; this premium on a saving of coke is a premium on working with a high pressure.

The explosion took place at 7.14 a.m. The guard of the train and the assistant station-master, who were both on the platform close to the engine, state, that the driver was on the boiler warming his coffee in the dome and holding the lever in one hand, and that the steam was blowing off all the time.

The accompanying sketch shows the state of the fragments after the explosion: which also demolished a large portion of the roof of the passenger shed.

London, Brighton, and South Coast Railway,

Secretary's Office,

London, May 3, 1853.

Having submitted to the Board of Directors your communication of the 21st ultimo, on the subject of the explosion of a locomotive boiler at the Brighton terminus on the 17th of March last, and enclosing a copy of Captain Galton's report thereon, I have been desired to inform you that such communication and report have been attentively considered by the directors.

I am instructed to hand you a copy of resolutions passed by the Board of Directors on the 4th ultimo, by which their Lordships will perceive that their principal suggestions had already been anticipated by the board.

I am also to transmit a copy of the report made by the company's locomotive engineer, after perusing the communications which I had the honour to receive from you.

I have, &c.,

FRED. SLIGHT,

Secretary.

London, Brighton, and South Coast Railway.

EXTRACT from the proceedings of the Board of Directors, April 4, 1853.

Resolved,—“ That Mr Craven be further instructed to provide each engine with a brass plate or other register showing the proper amount of pressure, which must not on any account be exceeded, and that he go report as soon as possible upon the best plan of a safety valve beyond the reach of the driver which he would recommend for general adoption.”Resolved,—"That the practice of giving premiums for the smallest consumption of coke be abolished, but that a similar amount be given each half year in premiums for general good conduct, as may be recommended b) the locomotive superintendent.”

Brighton, April 25, 1953.

DEAR Sir,

I have carefully perused the report made by Captain Galton, with reference to the explosion which took place at this terminus on the 17th ultimo, and I feel it my duty to make the following remarks thereon.

With reference to Captain Galton's observations as to limiting the pressure at which the engines may safely he worked, and also as to the tendency of coke premiums to induce the engine drivers to work their engines at a high rate of pressure—the directors will remember that this subject was fully discussed immediately after the explosion ; and I am proceeding, as far as practicable, to carry out the instructions which I then received from the board.

" The original builders of the engine, Messrs. Rennie, are stated by Captain Galton to have informed him, that according to the record in their books, the thickness of the plates of the cylindrical part of the boiler was, when new, three-eighths of an inch, and of the plates on the outside case of the fire-box, seven-sixteenths of an inch ; and that upon the subject of the safety valves the following is recorded, namely, limit of pressure of the safety valve not under the control of the engineer, sixty lbs.; the other valve under the control of the engineer, fifty lbs. working pressure.

I very much regret that I had no opportunity of offering any remarks upon this statement at the time it was made by Messrs. Rennie, but I beg to draw your attention to the following observations.

As regards the thickness of the boiler plates I cannot agree with Messrs.Rennie that there was originally any difference in the thickness of the cylindrical part of the boiler and the outside casing of the fire-box, but that both were made of three-eighth inch plate, which I considered a good thickness.

As regards the safety valves, I have examined some of our oldest engine drivers, and I have no doubt that the records shown by Messrs. Rennie to Captain Galton referred to the engines made by them in 1842, and not to Nos. 9 and 10 which were made in 1840 ; and from the evidence of Edward Jackson, one of our original and steadiest drivers, I learn that he drove some of the original engines made by Messrs. Rennie, and he can vouch for the fact that Nos. 9 and 10, when new, had the ordinary levers and spring balances to both safety valves, but that their last engines had what is termed a lock-up safety valve on the boiler.

Captain Galton was, therefore, misinformed as to the lock-up safety valve having been originally fixed on No 10, for such was not the fact.

The Board of Trade call the especial attention of the directors to Captain Galton's observations, on the impropriety of allowing the working pressure of locomotive engines to be increased beyond the limits fixed by the original constructors ; and Captain Galton states, that it was incurring a great risk to allow an old engine with a weak form of boiler, constructed for a working pressure of from fifty lbs. to sixty lbs. per square inch, to be worked to eighty lbs., and that this risk was much increased by placing both safety valves under the control of the driver, without even ordinary precautions having been taken to prevent him screwing them down probably to such a point as to prevent any escape of steam whatever ; and that whilst the thickness of the plates had diminished by wear as much as one-third in some places, the pressure was increased by as much as one-third, and that the safety valves were altered so as to place both under the control of the driver.

I have already explained that Captain Galton has been misinformed both as to the thickness of the plate on the outer case of the fire-box, and as to the supposed alteration of the safety valve on the boiler.

As to the other points, I am not aware that there even existing among locomotive engine builders such a practice as that of fixing the maximum pressure at which an engine should be worked. In the present instance, the pressure had not been increased without the introduction of longitudinal and others stays, sufficient to enable the boiler to bear such extra pressure. The fact was stated by me to Captain Galton, but it is not referred to in his report.

" Messrs. Rennie appear to have stated that they limited the working pressure when new at sixty lbs. per square inch, and while, on the one hand, Captain Dalton states that it was improper to exceed that pressure—he, on the other hand, states that the bursting pressure, if sound, should have been above 350lbs. per square inch, and was possibly from about 170 lbs. to 200 lbs.

These statements appear irreconcilable. I cannot believe that Messrs. Rennie are prepared to allege that their boilers were not safe at a much higher pressure than sixty lbs. ; nor do they appear to have ventured such a statement, although they allege that they limited the pressure to sixty lbs. ; and it is evident that they were safe at a much higher pressure, if it be a fact that the bursting pressure when new was 450 lbs., and as stated by Captain Galton, after twelve years' wear, 350 lbs.

If Mr. Fairbairn's formula, modified by Captain Galion to 350 lbs., is not correct, then I apprehend that Captain Galton’s calculations as to the cause of the explosion fall to the ground ; but, in any case, I have no hesitation in saying, that when No. 10 engine was delivered by Messrs. Rennie, it would have been prefectly safe to work at a much higher pressure than sixty or even eighty pounds per square inch ; for how could it be dangerous and improper to increase the pressure from sixty to eighty pounds on an engine which had not only been strengthened so as to bear the extra pressure, but of which the bursting pressure when new, was 450 lbs., and after twelve years service, 350 lbs.

"With regard to the question of the omission of ordinary precautions to prevent the drivers screwing down the valves, I beg leave to say that the safety valves of No. 10 engine were the ordinary valves in use throughout the country. The addition of ferules will not prevent an imprudent driver loading his lever, and thus partially, or entirely, closing the valve.

I entirely concur with the observations in the report as to the objections to leaving both safety valves under the control of the driver. This is a question that has long had the anxious attention of locomotive engineers; but as yet I have neither seen nor heard of any effectual plan for doing away with the evil, and I infinitely prefer the ordinary safety valve with a lever and Salter’s spring balance, to any lock-up valve which I have yet seen. I consider that those sent by Messrs. Rennie are very objectionable ; and only calculated to lead to mischief if any confidence were placed in them, for any driver can easily lock them, and render them worse than useless.

I may add that the experiments made by Captain Galton with the sister engine No. 9, and referred to in his report, were made when the boiler was naked, and stripped of its lagging. If the boiler had been in working order the pressure would, of course, have increased much more rapidly than shown by the experiments.

I have, &c.

F. Slight, Esq., Secretary

of the (Signed) J. C. CRAVEN.

London, Brighton, and South Coast Railway.Railway Department, Board of Trade,

Whitehall, May 4, 1853.

Sir

I am directed by the Lords of the Committee of Privy Council for Trade, to transmit to you the enclosed letter and report from the London, Brighton, and South Coast Railway Company, and to request that you will furnish their Lordships with any observations you may desire to make with reference thereto. I am, &c.,

J. L. A. SIMMONSR.E. Capt.Royal Engineers.

May 27, 1853.

Sir,

I have the honour to acknowledge the receipt of your letter of the 5th instant, referring to me a communication from the London, Brighton, and South Coast Railway Company, enclosing some remarks by Mr. Craven upon my report upon the subject of the boiler explosion, which took place on the 17th March at Brighton—and I beg to transmit to you the following observation, thereon.

In the first place, Mr. Craven states that I have been misinformed by Messrs. Rennie, upon two points.

The first point is, that the thickness of the plates as stated by them to have been three-eighths of an inch for the cylindrical part of the boiler, and seven-sixteenths for the case of the firebox—was in reality three-eighths all over. Upon this I have to observe, that in my remarks upon the diminution of thickness of the plates, I stated that I had found the thick- ness in parts to be one quarter inch, and that from what I had learned of the original thickness, this portion appeared to have been diminished by one third from its thickness when new ; from which it is evident that my argument had reference to a thickness of three-eighths, which Mr. Craven does not dispute, and not to the thickness of seven-sixteenths, which he considers from his practical experience never could have been the thickness of any part.

The next point is, that Messrs. Rennie have furnished me with incorrect information as to the safety valves which were upon the engine when new. These safety valves as recorded in Messrs. Rennie's books, would appear to have been one lever valve and one valve out of the control of the driver. Mr.Craven states that the oldest driver on the line thinks that the earliest engine made by Messrs. Rennie had two lever valves, and argues thence that the entry in Messrs. Rennie's books is inaccurate. As regards this point I have again consulted Messrs. Rennie, and seen the detailed drawings of the engines, which represent them with one lever valve, and one valve out of the control of the driver ; and as it is above twelve years since these engines were supplied, I am more inclined to believe the accuracy of Messrs. Rennie's books and drawings, than the accuracy of the memory of the oldest driver of the Brighton Company. In the next place, Mr. Craven observes, that I did not allude to his having introduced longitudinal and other stays into the boiler of the engine when the pressure was increased. As regards this I would remark, that the fact of his having done so did not appear to bear upon my observation, that " whilst the" thickness of the plates in the boiler had diminished by wear as much as one" third in some places, the pressure at which the engine was worked was" increased by as much as one third over the original pressure," because it was in the cylindrical portion that I found the diminution of thickness had taken place from three-eighths to one-fourth of an inch, and the stays mentioned would not have affected the strength of that circular portion.

Mr. Craven then goes on to say that " Messrs. Rennie appear to have stated that they limited the working pressure when new at 60 lbs. per square inch, and while on the one hand Captain Galton states that it was improper to exceed that pressure, he on the other hand states that the bursting pressure if sound should have been 350 lbs. per square inch, and was possibly from about 170 lbs. to 200 lbs. ; these statements appear irreconcilable. I cannot believe that Messrs. Rennie are prepared to allege that their boilers were not safe at a much higher pressure than 60 lbs., nor do they appear to have ventured such a statement, although they allege that they limited the pressure to 60 lbs., and it is evident that they were safe at a much higher pressure, if it be a fact that the bursting pressure when new was 450 lbs.—and as stated by Captain Galton, after twelve years wear, 350 lbs.

" If Mr. Fairbairn's formula, modified by Captain Galton to 350 lbs. is not correct, then I apprehend that Captain Galton’s calculations as to the cause of the explosion, fall to the ground, but in any case, I have no hesitation in saying that when No. 10 engine was delivered by Messrs. Rennie, it would have been perfectly safe to work at a much higher pressure than 60 or even 80lbs. per square inch, for how could it be dangerous and improper to increase the pressure from 60 lbs. to 80 lbs. on an engine which had not only been strengthened so as to hear the extra pressure, but of which the bursting pressure when new was 450 lbs., and after twelve years' service 350 lbs." Upon this I have to observe, that in assuming 350 lbs. as the burstingstrength of the boiler, if sound, instead of 450 lbs., as given by Mr. Fairbairn’s formula—I estimated the strength of a new boiler by Mr. Fairbairn's formula, and deducted a certain amount in consequence of the boiler in question having been made of longitudinal plates singly riveted instead of being made of plates bent round and doubly rivetted, as I understood the latter to be the construction of the boilers upon which Mr. Fairbairn's experiments were made.

I did not deduct for deterioration in quality or flaws, but I considered that the actual pressure at which the boiler burst was much under 350 Ibs. per square inch. from the circumstance of there having been only ten minutes between the time when the pressure was 80 lbs. per square inch and the explosion, for the last minute or two of which the steam was stated to have been blowing off furiously through the valves ; and Mr. Gooch's experiments clearly show how very small an aperture is required to allow the escape of all the steam which can be generated at a high pressure by a locomotive boiler when stationary ; and this diminution from the 350 lbs. I attribute to deterioration in strength due to some action either mechanical or chemical which appears to be continually at work in boilers.

In the next place, Mr. Craven does not agree with my observation that as the boiler when new was intended be worked at 50 lbs. or 60 lbs, pressure, is was hazardous to work it at 80 lbs. pressure when twelve years old and when the thickness of the plate had diminished in sonic places from three-eighths of an inch to one quarter of an inch, and he states that it is evident that it was safe to work at a much higher pressure than 80 lbs. if the bursting pressure with a quarter of an inch plate was 350 lbs. Upon this I have to observe, if the original makers of a boiler have allowed a certain margin of strength above the pressure at which they understood it was to be worked, and if a railway company have purchased an engine with such a boiler, with a knowledge of the pressure which the manufacturer has fixed for it to be worked at, it cannot be right to permit a permanent encroachment upon this pressure, besides which it is not desirable under any circumstances to strain iron to a point anywhere approaching its ultimate strength, especially in the case of a boiler which is subjected to strains from expansion and contraction at the same time that strains from pressure and other causes are applied.

Mr. Craven observes, that the addition of ferules to lever safety valves will not prevent an imprudent driver from loading his lever, and thus partially or entirely closing the valve. Upon this I would observe that it would, under such circumstances, require a very considerable weight to be placed on the lever before the valve would be entirely closed, and that no engine driver would so load his lever without deliberately intending to do so; and he would know that he was incurring risk, and that if discovered he would be liable to punishment. But, as regards the levers without ferules, a driver might screw one down and prevent it from acting, merely through carelessness, and without intending to incur danger.

I have, &c., DOUGLAS GALTON.Capt. Royal Engineers.

Railway Department, Board of Trade,

Whitehall, June 15, 1853.

Sir

I AM directed by the Lords of the Committee of Privy Council forTrade to acknowledge the receipt of your letter of the 3d May, on the subject of the explosion of the locomotive boiler, which occurred at the Brighton terminus on the 17th March last, and I am to state that it is with much satisfaction that their Lordships are informed that the directors had issued instructions having reference to the principal suggestions made in the report of the inspecting officer.

I am at the same time to transmit to you a copy of a further report of that officer, containing observations upon the report of the locomotive engineer of the company, and to request that you will direct the attention of the directors to those parts of it in which reference is made to the entries in Messrs. Rennie's books as to the manufacture of the engine, and the fact deducible therefrom, and from the evidence and admissions of the locomotive engineer, that after many years' use, and a great diminution in the thickness and consequent strength of the boiler, the locomotive engineer had allowed the pressure to be very considerably increased beyond that at which the engine was intended to be worked by the builder, and at which it was actually worked by the company after it came upon the line.

My Lords direct me to observe, that they cannot but think that such a proceeding was very improper, and that a very great degree of responsibility attaches to the locomotive engineer who sanctioned it.

I have, &c.,J. L. A. SIMMONS, Capt. Royal Engineer:

London, Brighton, and South Coast Railway,

Secretary's Office, London, September 13, 1853

Sir,

In reply to your letter of the 15th June last, directing the attention of the directors of this company to those parts of a further report by Captain Galton, on the subject of the explosion of the locomotive boiler at the Brighton terminus on the 17th March last, therewith inclosed, in which reference is made to the entries in Messrs. Rennie's books as to the manufacture of the engine, and the fact deducible there from, and from the evidence and admissions of the locomotive engineer, that after many years' use, and a great diminution in the thickness and consequent strength of the boiler, the locomotive engineer had allowed the pressure to be very considerably increased beyond that at which the engine was intended to be worked by the builder, and at which it was actually worked by the company after it came upon the line and in which you further observe that the Lords of the Committee of Council for Trade cannot but think that such a proceeding was very improper, and that a very great degree of responsibility attaches to the locomotive engineers who sanctioned it I am desired by the directors to inclose copies of the communications addressed by them to Messrs. Rennie on the subject.

The directors have received no reply whatever to their communications, which confirms them in their opinion, of the inaccuracy

of the statements made by that firm with regard to the engine in question.

I have, &c.

FRED. SLIGHT,

Secretary.

Secretary's Office, June 21, 1853.

GENTLEMEN,

I am desired by the board of Directors to address you on the subject of the explosion which took place at Brighton on the 17th March last, of the boiler of a locomotive engine formerly called the Eagle, which was constructed by you, and delivered to this Company about twelve years since.

The Inspector of the Board of Trade has made a report with reference thereto, casting some censure on the locomotive engineer of this company, apparently on a statement emanating from your firm, that the engine in question was, when turned out of your workshops, considered by you as unsafe at a higher pressure than sixty pounds to the square inch, and that this had been notified to this company, by whom that pressure had been subsequently increased.

This statement appears to be evidently founded on some misapprehension, as the Directors cannot suppose that the engine in question was so inferior to those of other locomotive manufacturers, as to require such an unusual limitation of pressure, nor can they discover any record of an intimation having been given to the company to that effect.

I am therefore desired to request that you will be good enough to give the Directors an explanation on these points, and more especially to inform them specifically, whether the engine in question was considered by you as unsafe at a higher pressure than sixty pounds to the square inch, and, if so, whether any notification of such opinion was ever given to this company.

I am, &c. F. SLIGHT,

Secretary.

Secretary's Office, July 26, l853.

GENTLEMEN,

I am desired by the board of Directors to address you on the subject of the explosion which took place at Brighton on the 17th March last, of the boiler of a locomotive engine formerly called the Eagle,' which was constructed by you, and delivered to this Company about twelve years since.

The Inspector of the Board of Trade has made a report with reference thereto, casting some censure on the locomotive engineer of this company, apparently on a statement emanating from your firm, that the engine in question was, when turned out of your workshops, considered by you as unsafe at a higher pressure than sixty pounds to the square inch, and that this had been notified to this company, by whom that pressure had been subsequently increased.

This statement appears to be evidently founded on some misapprehension, as the Directors cannot suppose that the engine in question was so inferior to those of other locomotive manufacturers, as to require such an unusual limitation of pressure, nor can they discover any record of an intimation having been given to the company to that effect.

I am therefore desired to request that you will be good enough to give the Directors an explanation on these points, and more especially to inform them specifically, whether the engine in question was considered by you as unsafe at a higher pressure than sixty pounds to the square inch, and, if so, whether any notification of such opinion was ever given to this company.

I am, &c. F. SLIGHT,Secretary

Railway Department, Board of Trade,

Whitehall, 22nd September, 1853.

Sir

I AM directed by the Lords of the Committee of Privy Council for Trade to acknowledge the receipt of your letter of the 13th instant, enclosing copies of letters addressed by you to Messrs. Rennie, respecting the engine, the boiler of which exploded Brighton, on the 17th March last.

My Lords direct me to observe, that from an examination of the reports of the inspecting officer of this Department on the subject of this explosion, it does not anywhere appear that he has made any statement of the nature of that to which, in your letter to Messrs. Rennie, you have alluded as emanating from their firm, viz., that the engine in question was, when turned out of their workshops, considered by them as unsafe at a higher pressure than sixty pounds to the square inch ; and that this had been notified to the Brighton Railway Company, by whom that pressure had been subsequently increased.

With reference to this statement, my Lords direct me to inform you that reference is made, in the report of their officer, to entries in Messrs. Rennie’s books, as to the construction of the safety valves upon the engine ; from which it appears, that when the engine was delivered to the company, it was furnished with one lever valve, and one valve out of the control of the driver; upon the latter of which, the pressure was limited to 60 lbs. on the square inch. It appeared also from the evidence, that this valve had been altered, and that the engine was worked at 80 lbs. pressure ; and that after a number of years, when the strength of the boiler must have been diminished, it not having been strengthened in its circular part in the meanwhile.

These facts appear to my Lords quite sufficient to call for the observations which their Lordships felt it their duty to make, pointing out the impropriety of the proceeding.

My Lords direct me further to observe, that there does not appear to be any statement in the reports of the inspecting officer of the nature of that referred to in year letter, that Messrs. Rennie had notified to the Brighton Company that they considered the engine in question unsafe at a higher pressure than 60 lbs. to the square inch ; but on the contrary, the inspecting officer observed in his report, that if the original makers of a boiler have allowed a certain margin of strength above the pressure at which they understood it was to be worked, and if a railway company have purchased an engine with such a boiler, with a knowledge of the pressure which the manufacturer has fixed for it to be worked at, it cannot be right to permit a permanent encroachment upon this pressure.

I am to add, that my Lords have direct me to transmit a copy of this letter, and of the previous correspondence on the subject of this accident, to Messrs. Rennie for their information.

I have, &c.

J. L. A. Simmons.

Captain Royal Engineers.