1972

HORSHAM

INVOLVING

BRIGHTON DRIVER

DENNIS GILLIAN AND SECONDMAN J.A. 'BUNG’ HARRISON

ON THE 8th JANUARY 1972

On Saturday, 8th January 1972, at Horsham Station, in the Southern Region, British Railways, a collision between a goods train and an electric passenger train at 12.53.

On a dull but clear day, the 12.24 Class 8 engineer's material train from Three Bridges to Chichester, consisting of 12 bogie wagons, one four wheeled wagon and two brake vans, and hauled by two electro-diesel locomotives working in multiple, ran past the Horsham Down Branch Line Home signal at Danger and collided at about 20 m.p.h. with the rear of the 12.02 Victoria to Portsmouth Harbour and Bognor Regis electric multiple-unit passenger train, consisting of 8 coaches, which was standing in the Down Line Platform. The passenger train was pushed forward some 200 feet by the impact and the rear coach was forced up underneath the station footbridge by the leading locomotive of the engineer's train. Both the rear coach and the leading locomotive were derailed and extensively damaged.

The emergency services were promptly alerted and 14 passengers and the guard of the passenger train, who were slightly injured or suffering from shock, were quickly conveyed by ambulance to Crawley Hospital. One of the passengers was detained overnight, but the remaining 14 people were discharged after treatment.

The driver and secondman of the engineer's train, Who took shelter in the electrical compartment, escaped injury although they were later treated for shock.

Four wagons in the centre of the engineer's train were derailed as a result of the collision. The eighth wagon was derailed on the immediate approach to an over bridge carrying the main Horsham-Crawley road (A.264) and it almost completely demolished one of the two piers supporting the bridge, before coming to rest on its side, wedged between the ninth wagon and the Down Line platform wall. The bridge deck, being carried on continuous girders and well braced, did not collapse, but the road was closed until 14.30 on Tuesday, 11th January, when the erection of a temporary pier of steel trestling was completed.

The coach, locomotive, and wagons were all rerailed by 17.00 on Sunday, 9th January, and the track under and adjacent to the road bridge, which had been extensively damaged, was repaired in time to allow normal services to be resumed with a speed limit of 5 m.p.h. at 06.15 on Monday, l0th January. During the time that the line was blocked trains were terminated at Crawley, Dorking, and Billinghurst Stations and a bus service was operated between Horsham and these points.

DESCRIPTION

The Site

Horsham Station lies some 300 yards south of the junction of the Branch Line from Three Bridges with the Mid-Sussex Main Line from London (Victoria and London Bridge) to Bognor Regis, approximately 37 miles from London.

The line from Three Bridges consists of two tracks, but from its junction with the Main line there are four tracks leading to the four platforms in the station. Both Main and Branch lines are electrified on the conductor rail system at 750v DC.

In the Down direction from Three Bridges to Horsham the line undulates gently until climbing at 1 in 162 for about & mile to a summit just short of Faygate. After passing through Faygate on the level the track falls for 3 miles 14 chains to Horsham.

Included in this is a length of 2 mile falling at 1 in 100 and a further length of over q mile falling at 1 in 159.

The Signalling

Horsham Signal Box, which is on the east side of the running lines at the junction of the lines from Dorking and Three Bridges, contains a 90 lever frame working mechanically the points and shunt signals near the signal box and working electrically those located further away. All running signals in the station area are three-aspect colour lights, except the Distant signals on the

Down lines from Three Bridges and Dorking which are two-aspect. AU running lines within the station limits are fully track circuited and an illuminated diagram provided in the signal box shows the track circuits that are occupied. The section of line between Littlehaven and Horsham is worked on the Absolute Block System, using standard three- position block instruments and bells; these are repeated at Wimblehurst Lane Level Crossing.

The Horsham Down Branch Distant colour light signal is located on the post of the Littlehaven Down Home semaphore signal, 1000yds from the Down Branch Home signal (CBP 21). The Distant signal shows no aspect when the Littlehaven Down Home signal is at Danger, a Yellow aspect when the semaphore signal is 'Off', but CBP 21 is at Red, and a Green aspect when the semaphore signal is 'Off' and CBP 21 is at Yellow or Green. It is first sighted at a distance of 250 yds from the signal.

The Down Branch Home signal (CBP 21) is a three-aspect colour light signal located 588yds from the signal box and 890yds short of the point of the collision. It also protects Wimblehurst Lane Level Crossing, being slotted with its Down Home signal (No. 2): it is located 31yds before the crossing and is interlocked with the level crossing gates. The crossing keeper has both block bells and block instrument repeaters to warn him when to close his gates across the road and clear his signals, and an indicator is provided in Horsham Signal Box to show when this has been done. The crossing keeper also has an indicator which shows when the signal is 'On' (Red) or 'Off' (Yellow or Green).

As is common practice in the Southern Region, the track circuit on the Down Branch line immediately before Signal CBP 21 is also the overlap track circuit, stretching 440yds beyond the signal. Thus the signalman at Horsham gets no indication from his track circuit diagram that a train has run past the signal at Red until it occupies the next track circuit which commences only 148yds from the signal box (450yds short of the point of the collision).

The Trains

The passenger train consisted of two 4car electric multiple-units; both the leading unit (4-CIG) built in 1970 and the rear unit (4BEP) built in 1959 being of all-steel construction. The coaches within each unit were permanently connected with buckeye couplings and the ends of each unit were fitted with side buffers and buckeye couplings. Both units were fitted with electro-pneumatic and Westinghouse air brakes.

The rearmost coach of the train, which was a motor open second brake, had a driving compartment in one of the rear corners, a combined guard's and luggage compartment, and then a vestibule leading to the open passenger section of the coach.

The two locomotives hauling the engineer's train, Nos. E6010 and E6027, were Class 73/2 1600/600 h.p. electro-diesels working in multiple on electric power. Each locomotive was fitted with air brakes which could either be operated by the straight air brake valve, or by the automatic air brake valve which, provided that the necessary train and main reservoir pipes were connected correctly, would enable the driver to apply the brakes on both locomotives and the 'fitted head' of 4 bogie 'Salmon’ wagons. Class 73/2 electro-diesel locomotives are fitted with a comprehensive arrangement of brake couplings and electric jumper cables to enable the locomotives to he used to work singly or in multiple with either electro-pneumatic braked passenger trains or air or vacuum braked hauled stock. In this case evidence showed that the main electric jumper cable was connected between the two locomotives and one of the two pairs of air train and main reservoir pipes located above the buffer beam. The vacuum pipe below the buffer beam was also connected although the vacuum brake was not in use, and also the two air control pipes; the diesel control jumper cable was not connected.

The engineer's train was marshalled as follows:-

Vehicles Electro-diesel locomotive E6027 & Electro-diesel locomotive E6010, Salmon DB996508, Salmon DB996406, Salmon

DB996418, Salmon DB996453, Brakevan DS56232, Salmon DB996389, Salmon DB996982, Borail DS64645, Salmon

DB996972, Salmon DB996947, Salmon DB996950, Salmon DB996308, Salmon DB996940, Lowmac DS61091, Brakevan

DS55456.

LOAD TOTAL 993 tons

4 The 'fitted head' comprised the first 4 'Salmon' wagons behind locomotive E.6010, each wagon being fitted with twin pipe air brakes. These were followed by brakevan DS56232, which was merely fitted with through pipes and a brake valve and thus provided no additional air brake power to the train. The theoretical combined brake power of the two locomotives, the fitted head, and the handbrake of the rear brakevan was 243 tons or 24.5% of the total weight, while the theoretical combined brake power of the leading locomotive and the handbrake of the rear brakevan alone was 86 tons or 8.1% of its total weight of 993

tons. The brake force required for the train was 160 tons and its maximum permitted speed was 45 m.p.h.

Damage to Trains

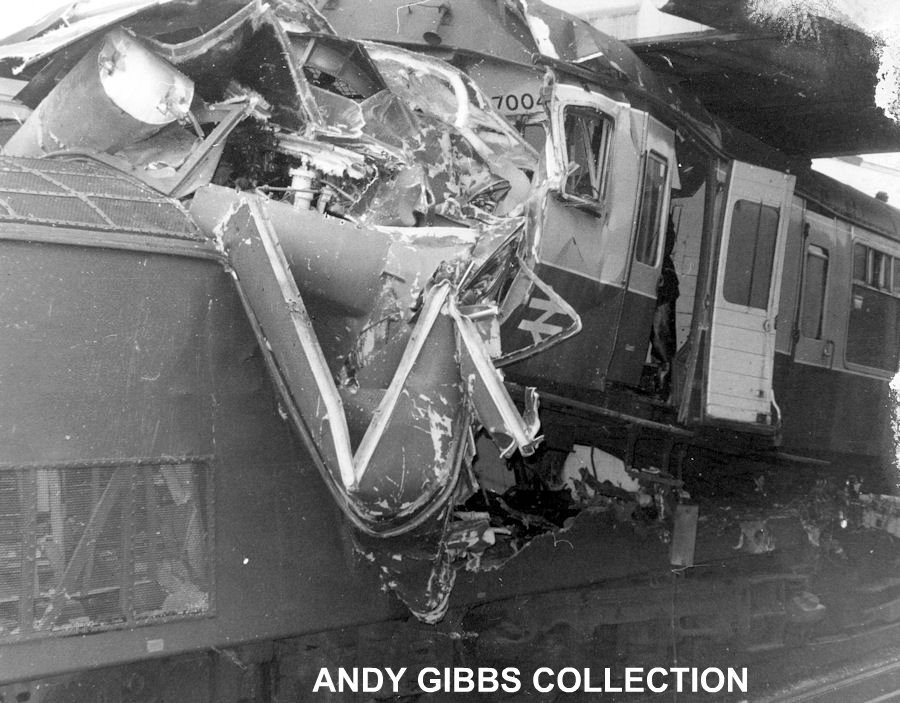

The coaches of the rear unit of the passenger train (BEP 7004) suffered considerable damage to both the underframes and bodies, while those of the front unit (CIG 7362) were virtually undamaged. The rearmost coach, which took the full force of the impact from locomotive No. E6027, had the driving cab completely demolished, the roof cut completely away from the cab end for approximately 10 ft, the body raised from the cab front to the vestibule doom, and the side panels and frame badly buckled and torn. In the passenger compartment, the seats against the rear vestibule partition were displaced, as were the rearmost two sets of back to back seats. The legs of the majority of the other back to back seats in the compartment had split through the holes of screws securing them to the seat ends and the screws securing the legs in the floor sockets were loose. However all body side seat fixings were secure with no signs of movement and it was not possible to lift the legs up and out of the floor sockets.

The body of locomotive No. E6027 was demolished from the leading cab to the middle of the locomotive. The roof was demolished over the same area and was also buckled back as far as the rear bogie. In addition to the leading cab, the engine room was demolished and the diesel engine pushed back into the compartment housing the electrical equipment, much of which was also damaged. The bogies of the locomotive were not extensively damaged, but the leading end of the underframe suffered considerably. The headstock was bent and fractured, the side and centre buffers were torn off, and the solebars bent. All brake pipes and jumper equipment were also badly damaged. The underframe at the rear end of the locomotive was not seriously damaged, nor was that of locomotive No. E6010.

Serious damage to the wagons of the engineer's train was confined to the sixth, seventh, eighth, and ninth wagons, the four wagons to become derailed. The seventh and eighth wagons were so badly damaged that they were broken up on site. Both these wagons shed their loads which were also seriously damaged.

Damage to Permanent Way, Signalling Equipment, Horsham Station, and Horsham-Crawley Road Overbridge

Damage to the track was in the main confined to the area under the Horsham-Crawley Road

Signalman W. W. Short was on duty at Horsham Signal Box at the time of the accident. He said that he accepted the 12.24 engineer's train from Three Bridges from the signalman at Littlehaven at 12.52. As it was running late, he decided to route it on the Down line in Horsham Station, behind the 12.02 passenger train from Victoria , instead of its normal booked path into the Down Loop. He had just given the 'Train out of Section' signal to Warnham for the 12.02 when he received the 'Train entering Section' signal for the engineer's train.

A short time later, while standing by No. 32 signal lever (the Down Line Starting signal) in readiness to restore it to normal after the passenger train had left the station, he saw the engineer's train closely approaching his signal box at a speed he estimated to be between 30 and 40 m.p.h. Short said that his view of the line from Three Bridges was obstructed by coaches standing in the sidings adjacent to that line and also confirmed that the track circuit on the approach side of the Down Branch Home signal (CBP 21) extended some 400 yards beyond the signal. Thus, even though he had been watching his track circuit indicator

diagram, he did not know that the engineer's train had run past signal CBP 21 at Danger until the train had nearly reached his signal box. He confirmed that the levers 20, 21, and 22 were in the normal position in the frame and that the aspect indicator of signal CBP 21 in the signal box showed the signal to be at Danger; the Calling On signal below signal CBP 21 was also indicated as being at Danger. 5 18. Short said that he had all the windows of the signal box closed at the time the engineer's train approached and he did not hear any whistling from the train's locomotive, although he would have expected to have done so if

the driver had been sounding 'pop' whistles. When he realised that the engineer's train was out of control, it was too late for him to take any action to prevent its colliding with the rear of the Bognor Regis passenger train. He immediately sent the 'Obstruction Danger' bell signal to Christ's Hospital, Warnham, and Littlehaven signal boxes, while the signalman who was just about to relieve him contacted the Electrical Control. Finally Short said that he did not hear any telephone bell ringing on the Three Bridges-Horsham omnibus circuit immediately prior to the engineer's train coming into sight.

The driver of the 12.02 Victoria-Portsmouth Harbour and Bognor Regis passenger train, Driver A. W. Price, said that he had a normal run down to Horsham, where he stopped in the Down Line Platform. He was holding his train with a pressure of about 10 1bs.sq in. on the air brakes, waiting for the starting bell, when the force of the collision at the rear of the train threw him backwards so that he hit his head on the rear bulkhead of the cab. He immediately made an emergency application of the automatic air brake and applied the handbrake, after which he made his way to the rear of the train to see what had caused the

collision. He then went to the Inspector's office to check that the necessary signals had been placed at Danger to protect the train and that the current had been isolated, after which he returned to his train to assist the passengers out of the rear coach.

Price said that the force of the collision moved his train forward about 3 coach lengths. He heard no 'pop' whistles prior to the collision and was taken completely unawares by it.

Guard E. S. Rodway, the guard of the 12.02 Victoria-Portsmouth Harbour and Bognor Regis train, was unable to attend my Inquiry but, in a statement taken by the Railway Officers on my behalf, said that he was travelling in the brake compartment of the leading coach of the rear unit. On arrival at Horsham he had alighted from the train and, on receiving a hand-signal from a member of the platform staff that the train was ready to depart, he re-entered his guard's compartment and was about to ring the starting bell when the collision occurred. The impact caused him to strike his head on the door jamb and threw him out onto the

platform. He then saw that another train had run into the rear of his train. At no time prior to the collision did he hear any 'pop’ whistles from the locomotive of the engineer's train.

Station Supervisor M. G. White, who was at lunch when the accident occurred, after being called by one of the railmen, immediately returned to the station where he checked that all the passengers were out of the passenger train and that the injured were being looked after by the ambulance men. He said that he then went to inspect the rearmost coach and the electro-diesel locomotive and, on looking between the two locomotives, noted that, although the air brake hoses of the locomotives on the side furthest away from the platform were connected, the brake isolating cocks were in the closed position, both at the rear of the

leading locomotive and at the front of the second locomotive. White said that he went to the signal box and reported what he had seen to Area Inspector Lloyd and the Station Manager. He did not see either the driver or the secondman of the engineer’s train.

Railman S. C. Madgwick was the crossing keeper on duty at Wimblehurst Lane Public Level Crossing at the time of the accident. Madgwick said that he normally closed the gates across the road for Down trains when he heard the 'Line Clear' signal being given on the block bells in his cabin. As soon as he closed his gates across the road, he pulled lever No. 2 in his frame which enabled the signalman at Horsham to clear signal CBP 21, but be noted that the indicator light in his cabin for signal CBP 21 was still showing Red when the engineer's train ran past it and over the level crossing. As the train passed him, he saw a lot of sparks coming from the wheels of the leading locomotive, but none from the second locomotive or any of the wagons. He estimated that the speed of the train as it passed him was about 10 m.p.h.

Madgwick said he heard the locomotive's whistle being sounded some time before the train reached the crossing, but no 'pop’ whistles were being sounded as the locomotives passed him. As soon as the train passed signal CBP 21 at Danger, he tried to contact the signalman at Horsham on the omnibus telephone circuit to warn him that the train had run by the signal, but he was unable to get a reply.

Signalman M. J. Pennells, who was on duty at Littlehaven Signal Box, offered the engineer's train to Horsham who accepted it in the normal way. He estimated that the train was travelling at 3540 m.p.h. as it passed his signal box, but he did not notice if the brakes of the locomotives or the train were being applied, nor did he hear the locomotive's whistle being sounded while the train was travelling towards Horsham. About two minutes later he received the 'Obstruction Danger' bell signal from the signalman at Horsham, whereupon he placed detonators on the Down line and took the necessary action to maintain his Down

signals at Danger.

Carriage and Wagon Examiner H. G. Parsons said that he carried out his examination of the engineer's train at Three Bridges after the first locomotive had been attached to the train, but before the second was attached. He examined both sides of the train and then looked at the air brake gauges in the brakevan marshalled behind the 'fitted head' of 4 'Salmon' bogie rail wagons; the brake pipe needle was registering about 75 p.s.i. and the main reservoir pipe needle showed 80p.s.i. 6 27. Parsons said that he then went to examine another train and that on his return the train crew were engaged in connecting up the second locomotive to the front of the train; they appeared to be having difficulty in starting up the diesel engines of the locomotives. He did not see if the brake and main reservoir pipes were coupled between the two locomotives, nor did he see the guard carry out the continuity brake test. Parsons explained that at no time did he carry out a brake test nor did he say anything to the guard which might have given him that impression.

ANDY GIBBS COLLECTION

The guard of the engineer's train was Conductor Guard E. C. Corner who, although he had only been in his present grade since June 1971, had been a goods guard since 1958. On his arrival at the engineer's yard, he examined his train and then awaited the arrival of the first locomotive. He watched this being coupled to the head of the train, making sure that the air brake hoses were coupled correctly and the cocks opened. Although he then went into the piped brakevan behind the 'fitted head' of 4 'Salmon’ bogie rail wagons, Corner said he did not carry out a brake test as he knew that a second locomotive had to be attached. While

waiting he decided to return to the brakevan at the back of the train.

Corner said that he returned to the front of the train to watch the second locomotive being coupled to the first; he was satisfied that the secondman coupled the two locomotives correctly. Having given the driver the details of his train, he said that he made his way hack to the brakevan at the rear of the 'fitted head' with the intention of carrying out a brake test, but he could not remember whether he actually carried out the test or not. While he was near the brakevan he heard the driver and the secondman shouting to each other concerning their inability to start the diesel engine of the second locomotive from the cab of the leading

locomotive and so he returned to the front of the train.

Corner said that he saw the secondman get in between the two locomotives and start to part the air brake pipes, one pipe actually being parted before the driver told him that "it is no good doing that, it is nothing to do with the control". The secondman then rejoined the pipes but Corner was unable to say whether or not he reopened the brake cocks. The driver then

left the locomotive to telephone his Motive Power Supervisor while Corner assisted the secondman in his efforts to start the diesel engines of both locomotives from the front locomotive. Corner said that in due course the secondman found that the auxiliary switch had not been switched over. Once that was done, Corner, watching the ammeter of the second locomotive, had confirmed that both locomotives could be controlled from the leading locomotive.

Corner said that, on the return of the driver, the latter was told that the control of the locomotives in multiple was now correct and so he checked with the shunter that it was all right for the train to pull up in readiness to set back into Three Bridges Station.

Corner then made his way straight back to the rear brakevan and they propelled the train into the station. Corner readily admitted that he did not carry out a continuity brake test during his walk from the locomotive back to the rear brakevan.

He said that he gave the driver the details of the train on an ordinary piece of paper, as he did not have a proper load slip. He had shown the train as having a 'fitted head', but had not calculated the brake power correctly, showing that it was some 40 tons more than it would have been had all the brakes been coupled up.

The run from Three Bridges to Horsham appeared quite normal to Corner. As was his custom, he applied the hand brake of the rear brakevan as soon as the train started to run on the falling gradient just short of Faygate and kept it applied throughout the rest of the journey to Horsham. He did not hear the locomotive's horn being sounded at all and, even when he saw that the Horsham Down Branch Home signal was displaying a Red aspect, he did not realise that the train was out of control, as with a long train the signal had usually returned to Red before the guard's van passed it. Corner said that he estimated that the train’s

speed as he passed over Wimblehurst Crossing was about 20 m.p.h., which he considered was normal if the train was not stopping in Horsham Station. However, as his brakevan passed Horsham signal box, he saw one of the 'Salmon' wagons in the middle of the train thrown up into the air and a number of other wagons become derailed: he managed to prevent himself being thrown to the floor by holding onto the wheel of the hand brake. Immediately the train stopped, Corner ran back past the signal box to protect his train, putting three detonators on the Down line at Wimblehurst Crossing and three more by the Down Home signal on the Dorking line. He then returned to Horsham Signal Box to report that he had protected both lines.

Corner told me that he had had a lot of training in carrying out the continuity brake test, both on passenger and on goods trains.

He was well aware of the regulations in the General Appendix concerning the working of the automatic air brake and in particular of paragraph 4 of the regulations, as amended by Supplement 4 to the General Appendix, which lays down how and when the vital continuity test must he made. Finally he confirmed that he had worked over the Three Bridges-Horsham route with engineer's trains previously.

The secondman of the engineer's train was Secondman J. A. Harrison, who was based on Brighton. On the morning of the accident he had worked electro-diesel No. E6027 with Driver Gillam from Haywards Heath to the engineer's yard at Three Bridges. On arrival there they set their locomotive back onto locomotive No. E6010 which was already coupled up to the engineer's materials train. Harrison said that he then coupled the two locomotives together including joining one of the two pairs of air brake pipes located above the buffer beam. 7 36. Harrison said that his driver and he had trouble in starting the diesel engine of the rear locomotive. The diesel engine of each locomotive started correctly using each locomotive's 'start' button, but it was not possible to start the second locomotive's engine from the cab of the front locomotive as one should be able to do if the locomotives are coupled for working in multiple. In an attempt to locate the fault, Harrison said he started to uncouple the air brake pipes between the two locomotives, having first closed the cocks on each locomotive, but his driver told him that this would have no effect in rectifying the fault and so he recoupled the pipes, but he now realised that he failed to reopen the brake

cocks on the two locomotives.

Harrison said that he obtained the diesel control jumper from the engine room of locomotive No. E6027 and went in between the two locomotives, telling his driver what he was going to do. Again his driver said that this would be of no assistance and so he returned the jumper to the locomotive's cab. His driver then went to telephone Control to tell them that they were in trouble.

While he was away, Harrison said that he and the guard continued to attempt to start both locomotives. Initially he had no success but, with the guard in the leading cab of the rear locomotive, he finally shut the diesel controller and opened the electrical controller and found he was able to start both engines using the auxiliary switch.

On his driver's return, Harrison explained to him how he had managed to start the diesel engines of both locomotives and the former got up into the front cab of the rear locomotive to check for himself that the locomotive had power on when the electrical controller of the front locomotive was operated. Harrison said he then replaced the diesel control jumper on its brackets in the engine room, while the driver set the train back slowly into Three Bridges Station. He was unable to say whether his driver carried out a running brake test on leaving Three Bridges as he was still in the locomotive's engine room.

Harrison said that they had a normal run from Three Bridges towards Horsham. His driver started to apply the locomotive’s straight air brake to gather the train up as soon as they saw the Horsham colour light Distant signal at Caution. The train brake was then applied and, as it had little effect, his driver made an emergency brake application, but again there was little reaction.

They passed the Horsham Down Branch Line Home signal on the immediate approach to Wimblehurst Level Crossing at Danger and they continued towards Horsham Station, travelling at about 20 m.p.h., with the driver sounding 'pop' whistles. As they passed Horsham Signal Box, his driver tried to attract the attention of the signalman, but was unable to do so. They then saw the rear of the train in the Down Platform and, realising that they were going to hit it, they went through the engine compartment into the electrical compartment where they braced themselves against the equipment, waiting for the collision.

After the collision, Harrison said that he and the driver got out of the locomotive via the rear cab. Someone drew his attention to the fact that the isolating cocks on the air brake couplings between the locomotives were closed and so he tried them to see if they had been loosened by the force of the collision, but they were quite stiff to move as he would expect them to be. It was then that he realised that he must have forgotten to open them at Three Bridges after attempting to part the brake pipes.

Harrison told me that he had received no training regarding coupling up electro-diesel locomotives in multiple for diesel working, that he had never done this prior to the day of the accident, and that he was not aware of the function of the diesel jumper. In his experience these locomotives were very rarely coupled in multiple.

Driver D. E. Gillam, a driver of some 10 years experience, confirmed that he worked electro- diesel locomotive No. E6027 from Haywards Heath to the engineer's yard at Three Bridges, where he backed onto the front of locomotive No. E6010. His secondman, Harrison, coupled the locomotives together, while he got up in the front cab of the rear locomotive to ensure that both the automatic and straight brake valves were in the shut position. He tried to start the diesel engines of both locomotives from the leading cab of locomotive No. E6027 to enable them both to be worked on diesel power without success, although he found he could start each engine from its own driving cab.

Gillam confirmed that Harrison went in between the two locomotives and started to uncouple the air brakes and that he had told Harrison to re-couple them as the operation of the air brakes could not affect the starting of the diesel engines. Gillam agreed that he did not check the position of the brake isolating cocks when Harrison had re-coupled them. He said that he then went away to telephone Control to inform them of their trouble and suggest that he isolated the electric pick-up shoes on the second locomotive and worked the train with the leading locomotive alone. On his return Harrison told him that he had managed to

obtain the control of both locomotives on diesel power using the electric controller of the leading locomotive: he checked and found that this was so.

Gillam said that when the two locomotives were being coupled together Guard Corner gave him full details of the train and told him that there was a 'fitted head'. Corner was still by the locomotives when they managed to get the controls functioning and Gillam said he instructed him to make his way back along the train and carry out a brake continuity test en route. Gillam said that be then got back up into the front cab of the leading locomotive and waited for the brake test to be carried out. While waiting he noted that the straight air brake on the secondman's side of the cab was on and so he got up, went over, and put the

brake valve in the off position. He then pulled the window down and looked out to see if anybody on that side of the train was signalling for him to set back. Gillam said that while he was looking out of the window he heard the compressor on the locomotive start. He pulled his bead back inside the cab and, looking across at the air brake gauges, saw the needle of the main reservoir gauge moving and he assumed that the guard had carried out a brake test. He admitted, however, that he saw no movement of the train brake pipe needle.

Gillam then returned to the driver's side of the cab and, on receiving a signal from the shunter, set back slowly into Three Bridges Station. He said he had no difficulty in bringing the train to a halt behind the subsidiary signal in the station using the combined train and locomotive brake. He then changed to electric power and, as soon as the signal cleared, he set out for Horsham. I asked Gillam whether he carried out a running brake test after leaving Three Bridges and was told that he had not, since he was satisfied that the brakes on the train were operating satisfactorily.

The journey from Three Bridges to Littlehaven was quite normal and Gillam did not apply the brakes at all until, while travelling at about 42 m.p.h., he saw the Horsham Down Branch Distant signal at Caution. Then, after buffering the train up using the locomotive's straight air brake, he made an initial application with the automatic brake. As this did not appear to have any effect, he made a further brake application and, when his secondman told him that the Horsham Down Branch Line Home signal was at Danger, he made a full emergency application and operated the locomotive's sanding equipment. This did not have any appreciable effect in reducing the train's speed and so he started to sound short blasts on the whistle to indicate that the train was running away.

As the head of the train passed over Wimblehurst Level Crossing at about 30 m.p.h., Gillam said that he signalled to the crossing keeper to warn him that the train was out of control. The train continued to push the locomotive through the junction and past Horsham Signal Box, at which point he saw that the train was routed along the Down line and not into the Down loop where it was booked to stand. He then saw the red blinds in the indicator panel at the rear of a passenger train standing in the Down Line Platform and, realising that a collision was inevitable, he and the secondman quickly left the cab and passed through

the engine room into the electrical compartment where they sat on the floor and braced themselves in preparation for the impact.

Gillam was unable to tell me the speed of the train when they left the driving compartment, nor was he able to estimate the speed at the time of impact.

After leaving the locomotive via the rear door, Gillam said that he went to the Inspector's office to telephone for the emergency services, but failed to contact the operator. He therefore returned to the platform and climbed into the rear coach of the passenger train to assist the passengers out onto the platform.

Gillam told me that he took no steps to protect the adjacent line as they were within station limits, nor did he take any steps to make sure that the current was isolated. I asked him if he examined the air brake isolating cocks between the two locomotives after the accident and he told me that his attention was drawn to the fact that the cocks were shut and the handles in the lowered position. He thought initially that they might have become closed as a result of the collision but when he saw his secondman try them and they were very stiff to operate, Gillam said he accepted that the brake cocks must have been closed when they left

Three Bridges.

Finally I questioned Gillam concerning his training on the coupling of electro-diesel locomotives in multiple for working on diesel power. He told me that he had had three weeks basic training on electro-diesel locomotives including their coupling in multiple and he had also been issued with a Coupling Instruction Guide for Multiple Working of Electro-Diesel locomotives. He said he had very rarely coupled up locomotives for working in multiple using their diesel engines, in fact he could not remember when he had last carried out such a connection. He now realised that had he connected the diesel control jumper cable between the two locomotives he would have been able to start the diesel engines of both locomotives without difficulty from the leading cab.

This collision was caused by the failure of Secondman Harrison to open the air brake dual isolating cocks on the two locomotives after he had recoupled the pipes when the engineer's train was standing in the yard at Three Bridges, by the failure of Driver Gillam to check that the brakes were correctly coupled, and also by the failure of Guard Corner to carry out the brake continuity test. This resulted in the air brakes of the rear locomotive and of the 'fitted head' of four bogie 'Salmon' wagons being isolated from those of the leading locomotive, the lack of brake power causing the train to run out of control down the falling gradients on the approach to Horsham on the line from Three Bridges. Had the full brake power of the train, some 243 tons, been available when Driver Gillam applied the brakes on passing the combined Littlehaven Down Home and Horsham Down Branch Distant signals at about 42 m.p.h. he would have had no difficulty in bringing his train to a stand short of the Horsham

Down Branch Home signal which was at Danger.

While Secondman Harrison is to blame for not opening the air brake dual isolating cocks on the two locomotives, Guard Corner is to blame for failing to carry out the brake continuity test from the rear of the 'fitted head' before the train left the engineer’s

yard at Three Bridges and Driver Gillam is to blame for failing to ensure that the brake test had been correctly carried out. I do not consider that Gillam was in any way justified in assuming that the brake continuity test had been carried out on seeing the needle of the main reservoir gauge move: he should have insisted that Corner carried out the test while he observed the fall and rise of pressure on the locomotive hrake pipe pressure gauge. The regulations concerning the Brake Continuity Test, contained in the Regulations for Working the Automatic Air Brake on Locomotive Operated Trains in Supplement No. 4 to the General Appendix to Working Timetables and books of Rules and Regulations, dated 27 March 1971, and in operation at the time of the accident, clearly state:-

"4.1.1. The Driver and Guard must co-operate in making this VITAL test which is for the purpose of proving the continuity of the brake pipe throughout the fitted portion of the train."

"4.3.3. The Guard must:- (a) If a Brake Van is the Rear Vehicle:-

Open the brake van emergency air brake valve for -a minute and observe that the brake pipe pressure falls. The Guard must then close the valve and observe that the brake pipe pressure rises to approximately 70 p.s.i."

"4.3.4. The Driver must observe the resulting drop in brake pipe pressure and subsequent rise to approximately 70 p.s.i."

"4.3.7. THE DRIVER MUST NOT START THE TRAIN UNLESS HE HAS OBSERVED THE FALL AND RISE OF PRESSURE ON THE LOCOMOTIVE BRAKE PIPE PRESSURE GAUGE.”

I am satisfied that both Corner and Gillam were fully aware of the importance of carrying out the brake continuity test on the air-braked train before starting the journey. Unlike the staff on other Regions of British Railways, those in the Central Division of the Southern Region have been accustomed to using air brakes and carrying out air brake continuity tests for many years and I can only conclude that their failure in this instance resulted from a lack of discipline on their part. The difficulties encountered in coupling up the two electro-diesels for working in multiple, using their diesel engines, caused through lack of knowledge of

the correct procedures, undoubtedly disrupted the train crew's normal routine and may possibly have contributed to the omission on the part of Corner and Gillam to carry out the brake continuity test. This in no way excuses Gillam however from failing to carry out a running brake test between Three Bridges and Horsham in accordance with paragraph 6 of the Regulations referred to in paragraph 52. Such a test could have been carried out on the falling gradients between Crawley and Ifield or when running through Faygate and would almost certainly have revealed the shortage in brake power.

I am also satisfied that Signalman Short was not aware that the engineer's train had run past the Horsham Down Branch Home signal (CBP 21) out of control in time to direct it into the Down Loop Platform and thus avoid the collision. By the time that the next track circuit showed occupied and Short could see the train closely approaching. the facing connections between the train and the Down Line Platform were track locked.

No less than five accidents caused by air-braked trains running out of control or failing to stop within the normal braking distance, together with an incident where a similar train ran out of control over a considerable distance without causing an accident, occurred between October 1971 and August 1972, including the serious collision between two goods trains near Beattock on 6 October 1971 which was the subject of a formal Inquiry by Major Rose. In his Report on that accident Major Rose stressed that in every case referred to above and also in a number of earlier accidents the brake continuity test was either omitted or not carried out properly. Thus the cause of the accidents, in nearly all cases the rendering inoperative of the whole or part of the air brake system by a failure to open the air brake cocks or to connect the air brake hoses correctly, which the continuity test would have revealed, was not discovered until it was too late.

As stated by Major Rose, most of these accidents resulted from a lack of discipline on the part of train crews, combined in some cases with a lack of knowledge and, following discussions with the Officers of the British Railways Board, steps were taken to

improve the standard of air brake training and to tighten up the application of the regulations. During more recent discussions with the Railway Officers, the Railway Inspectorate was assured that the importance of the Air Brake Continuity Test had been

emphasised to all staff including all trainmen: also that the importance of adhering to the regulations and the discipline of ensuring that they were properly carried out were being stressed during training. Consideration had also been given to the following ways of specifically improving the efficiency of train crews and yard staff in this matter:-

a. A thorough examination, both theoretical and practical, in the air brake test procedure to be included in guards', supervisors’, and any other appropriate staff's biennial examination;

b. Refresher courses to be given to the staff referred to in a. where required;

c. The attention of staff to be drawn specifically to the introduction of any new or extended working of air braked trains;

d. Divisional Inspectors and Area Managers to undertake spot checks to establish that the Brake Continuity Tests are being properly carried out. Yard and Station Supervisors to spend as much time as possible supervising brake tests being carried out;

e. An addendum to the Braking Instructions contained in the Driver's Manual, drawing the attention of drivers again to the absolute necessity to observe the Air Brake Continuity Test, to be issued.

I am glad to report that a major change in the procedure in carrying out the Brake Continuity Test has been introduced on British Railways with effect from 11 June 1973 designed to overcome the previous difficulty of establishing between the driver and the guard that any reduction in the driver's brake pipe pressure gauge and subsequent rise was a direct result of the guard carrying out the brake test. Full details of the new procedure are given at Appendix 'A' to this report: the most important alterations in procedure are:-

a. The driver must move the automatic brake valve in the leading driving compartment to the Running position and check that approximately 70 p.s.i. is registered on the brake-pipe pressure gauge. He must then move the brake valve to the Shut Down/Neutral position without a pause and retain at least 60p.s.i. on the brake pipe pressure gauge.

b. When the guard gives the particulars of the train to the driver, the latter should inform the former that he is ready to carry out the brake continuity test.

c. The guard must then, without delay, make his way to the rearmost air braked vehicle and either open the brakevan emergency air valve or the brake pipe cock, until all air is exhausted.

d. The driver must observe that the brake pipe pressure has dropped to zero in his leading driving compartment and that it does not start to rise again.

e. The driver must not start the train unless he has observed the fall of brake pressure and that it has remained at zero until he has moved the automatic brake valve to the Running position.

The Chief Mechanical and Electrical Engineer, British Railways Board, has also discussed the possible use of the Swedish mechanical device referred to by Major Rose, with the Officers of the Swedish Railways, who informed him that the device was designed specifically so that the drivers of very heavy iron ore trains are made aware immediately a train becomes divided and that it did not in any way replace the Air Brake Continuity Test. Only a very small number of these devices, consisting of a pressure impulse sender at the rear of the train and a special impulse receiver on the locomotive, have been made and apparently they have given considerable trouble despite many modifications. The Officers of the British Railways Board do not consider the device suitable for adopting for general use in proving that the air brake system of a train is properly connected and working

correctly, and I accept this view.

I have no doubt that the action outlined in paragraph 56, coupled with the introduction of the more positive procedure in carrying out the Air Brake Continuity Test, is already resulting in train crews and yard staff becoming more aware of the vital importance of the test and in an improvement in the standard of discipline in carrying it out. I am glad to record that no more

accidents of this nature have been reported to the Railway Inspectorate since August 1972 and I hope that the action taken will continue to result in the elimination of such accidents. If further accidents do occur to air braked trains due to the failure of the train crew to carry out the Air Brake Continuity Test, however, I consider that action should be taken to develop a mechanical device that would either make it impossible to start a train if the air brake system was not properly connected and in working order, or would indicate positively to a driver that the correct air pressure was present and available throughout all the fitted

vehicles in a train.

Finally, I recommend that the Southern Region take the necessary steps to ensure that all drivers passed to drive electro-diesel locomotives are thoroughly competent in coupling up their locomotives correctly for working in multiple when the locomotives are using their diesel engines. The existing arrangements for training drivers to operate electro-diesel locomotives should also be examined to ensure that adequate training in the coupling up of these locomotives to work in multiple under diesel power is given.

E6027 at Slade's Green depot in 1972

just before being cut up there after the accident at Horsham

RICHARD FERRIS COLLECTION